Electrostatic Discharge Matting: Safeguarding Industries from Shocking Dangers

What is Electrostatic Discharge?

Electrostatic Discharge. What is it? Electrostatic discharge (ESD) refers to the sudden flow of electricity between two objects at different electrical potentials. The extent of the impact of ESD becomes evident when we experience a discharge. This could be a subtle shock at around 2000 volts to a noticeable ESD shock at over 4000 volts. If you hear a sound during a discharge, it likely involved voltages between 3000 and 5000 volts, while the presence of a small blue spark indicates an even higher voltage, exceeding 10,000 volts.

Especially in the winter when air becomes drier, static electricity can easily build up with friction while walking or moving, even shifting in your office chair van produce up between 150 – 200 Volts of static electricity.

How an Electrostatic Discharge Happens:

1. Generation of Electrostatic Charge – ESD occurs when two objects with different electrical potentials come into contact or close proximity. When this happens, one object can transfer electrons to the other, creating an imbalance in charge.

2. Electrostatic Discharge – If the charge imbalance becomes significant, it can result in a sudden and rapid flow of electrons, also known as a discharge, from the charged object to the less charged or uncharged object. This discharge can produce a spark or an electrical current.

3. ESD Damage – Electronic components and integrated circuits are highly susceptible to ESD. Even a small ESD event, which may not be noticeable to humans, can create a voltage or current that is far higher than the components can handle, leading to permanent damage or latent defects.

ESD: A Benefit?

ESD can be a benefit or a risk depending on its use. A combustion engine or even a feather duster, for example, use ESD in order to function. But for some things, ESD is a huge risk and can cause problems like damage or even explosions such as in electrical component manufacturing or in fuel handling.

ESD is used in everyday life without most people realizing it in things like:

- Gas stoves

- Dusting tools (feather dusters, microfiber cloths etc)

- Electrical Discharge Machining (EDM) used in metal working

- Powder coating (coating products or items in powder coated paint for example)

But when is it a risk?

ESD becomes a risk for sensitive and volatile equipment. This is because the discharge can cause an electrical surge which can cause damage that might not even be seen by the naked eye. Static discharge can be a concern for many industries including in laboratories, automotive manufacturing, sensitive electrical equipment, servers, packaging and more.

It’s especially a risk for:

- Sensitive electronic equipment (think microchips)

- DNA sequencing

- Packaging environments

- Work spaces with a lot of movement (packing lines, cashiers, warehouses)

Still Stuck?

Justrite provides a 360-degree survey that will help you understand the present and any potential safety issues at your workplace. Schedule your FREE workplace safety survey today!

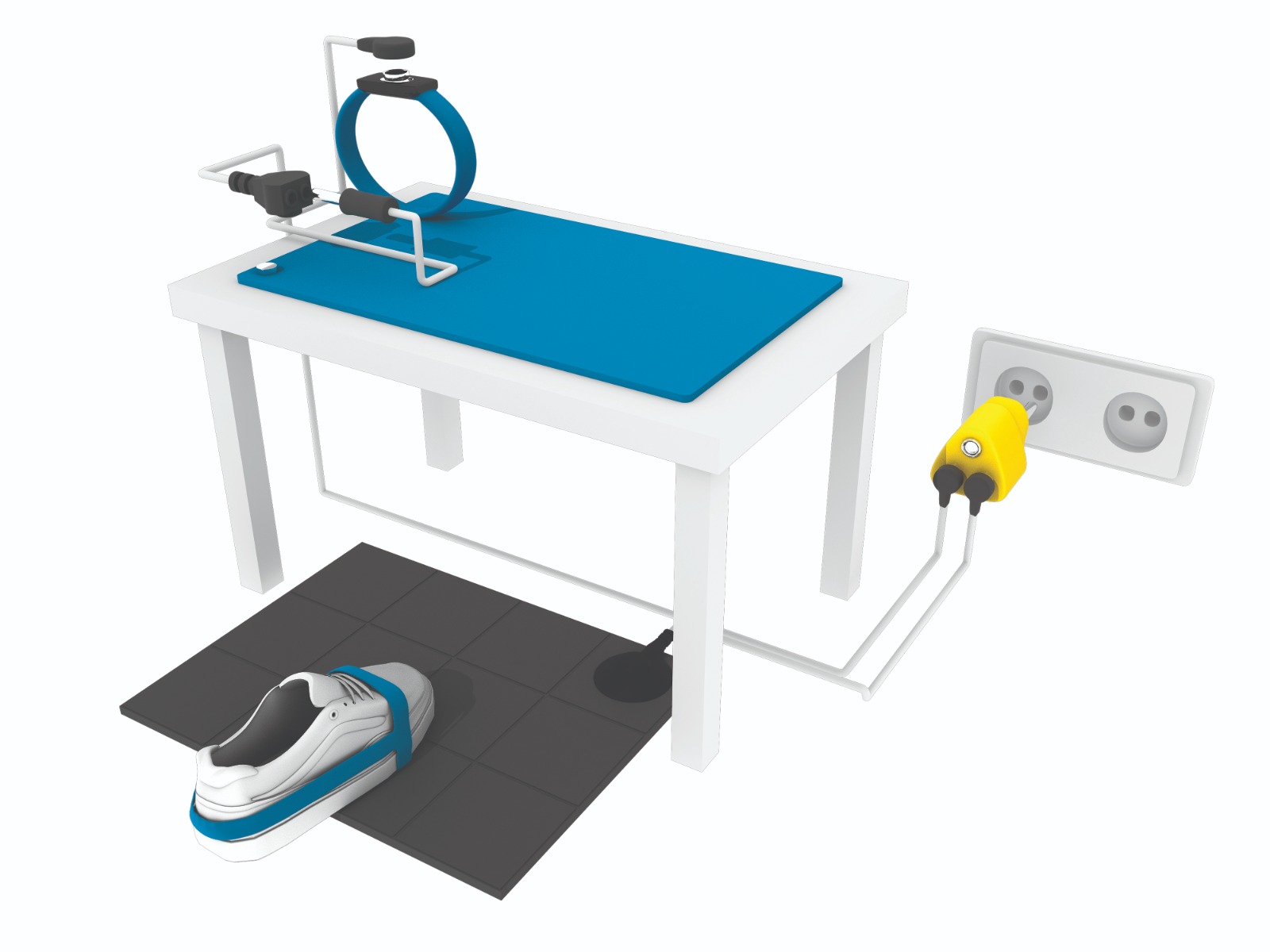

Preventing damage from ESD and the solution

To reduce the risk of shock injuries, damage and fire hazards, ESD control measures and devices are used such as ESD wrist straps, ESD mats, and ESD clothing which are designed to dissipate or ground electrostatic charges from people working with sensitive electronic devices. All conductors in the environment, including personnel, must be grounded to the same electrical ground point

ESD Mats are a great solution to preventing damage caused by ESD in industrial, laboratorial, and packaging industries. ESD matting is an invaluable solution in these industries because it covers the entire floor of the working area which protects all people working and any equipment by rapidly dissipating any static electricity before it can accumulate to harmful levels. In addition to this our anti-fatigue ESD matting provides anti-fatigue relief to employees who are required to stand for extended periods such as in clean rooms, car assembly, or packing where fatigue can be a significant issue. The cushioning effect of ESD matting reduces the strain on employees' legs and backs, making their work environment more ergonomic.

Notrax is one of the few flooring manufacturers that provides the most stable ratings. We have a wide range of ESD matting options covering linear lengths ideal for packing lines or modular solutions which are ideal for workstations or larger configurations. Notrax ESD matting meets or exceeds industry standards for ESD protection, such as ANSI/ESD S20.20 and ANSI/ESD STM7.1

For even greater protection we also have a full range of ESD accessories including wrist straps, heel grounders, earth bonding plugs, grounding points and complete your solution we also provide an ESD mat cleaner to safely clean and retain the ESD properties of your matting.

Our static dissipative vinyl work surfaces, conductive runners and table liners not only support static loads from conductive items but also establish a common grounding point for tables, employees, and conductive materials. This ensures controlled grounding, facilitating the safe dissipation of static electricity.

If your business relies on sensitive electronic equipment or operates in environments prone to static electricity, Notrax’s range of ESD matting and accessories is an essential solution for industries where static electricity poses a significant threat.

Find a Distributor

We only sell through qualified distributors. To locate a distributor in your area, click below and fill in the form.

Industries

Chip Manufacturing

ESD matting is vital in chip manufacturing, safeguarding electronic components from electrostatic discharge. By dissipating static charges and grounding workstations, it prevents damage, ensuring the integrity of semiconductor devices.

DNA Sequencing

ESD matting is essential in the DNA sequencing industry to protect sensitive equipment from electrostatic damage. By providing a controlled environment that dissipates static charges, it ensures the integrity of delicate sequencing instruments and prevents data corruption.

Logistics

ESD matting is a crucial element in logistics, shielding electronic components from electrostatic discharge during handling and transport. These mats, strategically placed on workstations, dissipate static electricity, ensuring a secure environment for employees working with sensitive devices.

Laboratory

In laboratories where precision electronic instruments and devices are prevalent, ESD matting ensures the protection of sensitive equipment from potential damage caused by electrostatic discharge. These mats create a static-free work zone on laboratory benches, safeguarding both personnel and delicate electronic components.

Packaging

In packaging facilities where electronic components are handled, ESD matting is strategically placed on workstations and assembly lines, ensuring a static-free environment. By minimizing the risk of static charges, these mats contribute to the protection of valuable electronics, reducing the potential for defects or failures caused by electrostatic discharge.

Maintenance

In workshops or maintenance areas where electronic components are prevalent, ESD matting serves as a protective layer on work surfaces, ensuring the safety of both personnel and valuable equipment. By minimizing the risk of static charges, these mats contribute to the longevity and reliability of electronic devices.

Need more help?

We have a local team who are always ready to assist you in answering your questions and guiding you to the right products to enhance the safety at your workplace.

Contact us

Find a Distributor

ESD Brochure

STUD - E (TM) Site Surverys